How to Do Common Lawn Sprinkler Repair Service to Keep Your Watering System

Issues such as reduced water pressure, clogged nozzles, and broken heads can substantially influence the system's efficiency. Cleaning or unclogging nozzles and replacing malfunctioning heads are fundamental jobs that can improve water distribution. Adjusting water stress to the optimal variety of 30-50 psi makes sure consistent coverage.

Identifying Common Sprinkler Issues

A properly maintained lawn sprinkler is critical for effective lawn care, however even the ideal systems can encounter troubles. Determining usual sprinkler issues early can stop considerable damage and ensure the durability of your watering system. One regular trouble is low tide pressure, which can cause irregular watering and dry spots on your yard. This concern commonly originates from leaks in the pipelines, damaged lawn sprinkler heads, or clogs within the system.

An additional widespread problem is sprinkler heads that do not appear or retract properly. This breakdown might be as a result of particles blocking the mechanism or a worn-out spring. Furthermore, misaligned sprinkler heads can result in water being splashed onto sidewalks, driveways, or other unintended areas, causing water wastefulness and not enough coverage of your yard.

Cleansing and Unclogging Nozzles

When taking care of typical sprinkler issues, addressing clogs is critical for maintaining optimal system efficiency. Over time, debris such as dirt, yard cuttings, and natural resource can build up within the nozzles, blocking water circulation and lowering irrigation efficiency. To guarantee your sprinklers run properly, normal cleaning and unclogging of nozzles is vital.

Begin by turning off the watering system to prevent any unintentional water discharge. Carefully eliminate the nozzle from the sprinkler head. For extensive cleansing, soak the nozzle in a blend of water and vinegar or a business cleaning service created to liquify mineral deposits.

Rinse the nozzle under running water to get rid of any staying particles and reattach it to the sprinkler head. Turn the system back on and observe the water distribution to ensure the blockage has been removed. Regular upkeep of sprinkler nozzles can substantially enhance the long life and efficiency of your watering system.

Replacing Broken Sprinkler Heads

Replacing busted sprinkler heads is a crucial step in preserving a reliable irrigation system. When a lawn sprinkler head ends up being damaged, it can result in water wastage and uneven coverage, which can adversely influence the wellness of your yard or garden. The initial step is to determine the malfunctioning head, normally noticeable with uneven water spray patterns or water merging around the base.

Begin by switching off the water system to avoid any unnecessary more helpful hints splilling. Use a shovel to meticulously dig around the lawn sprinkler head, ensuring you do not harm the bordering piping. Once exposed, loosen the damaged head from the riser, keeping in mind of the make and design to guarantee you acquire a suitable substitute.

Screw the brand-new sprinkler head onto the riser by hand, guaranteeing it is snug however not extremely tight to stay clear of harming the threads. Turn the water supply back on and evaluate the new head to ensure it is working properly, making adjustments as required.

Adjusting Water Pressure and Insurance Coverage

In order to optimize the performance of your irrigation system, readjusting water stress and protection is essential. Proper water stress makes sure that each sprinkler head runs effectively, dispersing water uniformly across your lawn or garden. To start, measure the water stress at the main supply line using a pressure gauge. Perfect stress commonly ranges from 30 to 50 psi. If the pressure is expensive, think about setting up a pressure regulatory authority to stop damages to sprinkler heads and pipes.

Following, concentrate on adjusting sprinkler head protection to eliminate dry spots and overwatered locations. For rotating heads, readjust the arc and radius setups making use of a screwdriver to change the direction and range of water flow.

Make certain overlapping protection between surrounding sprinkler heads to prevent missed out on locations. Also, look for any kind of blockages such as plants or structures that may obstruct water circulation. By adjusting water stress and make improvements sprinkler head protection, you can maintain a rich, healthy landscape while preserving water sources efficiently.

Normal Maintenance Idea

Next, check for leaks in the watering lines. Monitor the water pressure during operation; fluctuations can suggest covert leakages or obstructions.

Readjust the system's timer setups according to seasonal water demands. Overwatering or see page underwatering can hurt your landscape and waste sources. Furthermore, evaluate the rain sensor and ensure it is working properly to avoid unnecessary watering throughout rains.

Verdict

Dealing with common problems such as reduced water pressure, clogged nozzles, and broken heads can significantly boost system efficiency. Cleaning up nozzles with a great needle and vinegar, changing faulty heads, and changing water pressure to 30-50 psi are critical steps.

Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Alisan Porter Then & Now!

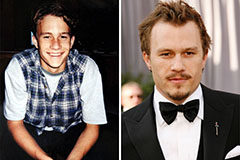

Alisan Porter Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Shane West Then & Now!

Shane West Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now!